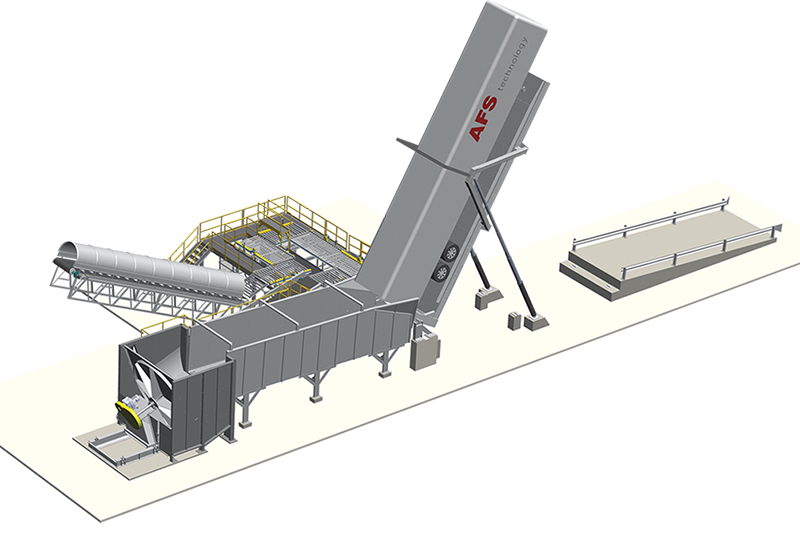

Scrap Tire Handling

Our materials handling systems have been specifically designed for scrap tires. The equipment involved automates many of the labor-intensive tasks relating to unloading, storing, sorting and transport of scrap tires to their end-use point. Tire Handling System configurations can be customized to fit your space allotment and desired level of automation.

The components of a Scrap Tire Handling System typically include:

Receiving & Storage

For full automation, trailers are driven onto a platform and tipped to unload tires directly into a Live Bottom Hopper. Equipment can be modified to accept shipping containers, front-end loaders, and finer bulk materials.

Equipment Used:

Tire Specifications: Scrap tires up to 54″ in diameter (1372 mm).

Truck Sizes/Types: Up to 53′ (16.2 m) trailers.

Receiving Rate: Up to 6 trailers per Tipper, per Hour w/ standard hydraulics.

Storage Capacity: Up to 22 tons; 2200 car passenger tires, per Hopper.

Separation & Refinement

Tires are discharged from the Hopper one at a time where they enter an inspection station that places tires in single file and sorted so that all tires exiting the station are fit to be fed into the kiln.

Equipment Used:

- Rotary Disk Tire Separator

- Discharge Conveyor

- Separation Refinement

- Conveyor System

Discharge Rate: 14 Tires Per Minute

System Options: Rim Detection | Rolling Reject Bins | Remote Surveillance | Tire/RDF Sorting