Precalciner Fuel Systems

Typically, the maximum fuel substitution for whole tires introduced on or falling to the feed shelf in Precalciner Kilns is less than 5%. Above this rate, the sulfur cycle volatilization in the kiln is too high to maintain stable operation without a significant loss in production.

To raise tire fuel substitution rates while maintaining process control, AFS Technology has designed two systems which use the concept of Suspension Burning to enable complete combusion of tires above the feed shelf – allowing for higher substitution rates and greater process control.

Feed Shelf Firing

Feed Shelf Firing For Preheater & Precalciner Kilns, AFS Technology provides automated fuel feed systems that introduce Whole Tires and other Bulk Fuels to the feed shelf for staged combustion. The fuel is gravity-fed in an environment designed to maintain negative pressure and minimize the introduction of outside air for ...

Learn More

Learn More

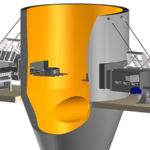

Rack Suspension Burner

Rack Suspension Burner Our Rack Suspension Burner is designed to feed whole tyres onto a high-temperature alloy Suspension Rack – also known as the “fork” or “fingers” – which enables the tyre to remain in suspension while burning inside the walls of the calciner. Typically placed above the tertiary air ...

Learn More

Learn More

Tire Skewer Suspension Burner

Tire Skewer Suspension Burner AFS Technology's patented Tire Skewer Suspension Burner takes advantage of the doughnut shape of the tire to hold it in suspension for 100% fixed carbon burnout. With this method, multiple tires can be securely suspended in the high gas velocities of the riser duct or feed ...

Learn More

Learn More