Alternative Fuel Systems

With over 20 years experience designing tire fuel systems for cement plants worldwide, the staff at AFS Technology has developed leading-edge innovations in tire handling automation and fuel feed systems for all major kiln types. Our systems are custom designed for each kiln to get the most out of its tire fuel usage while maintaining control over process and emissions.

Solid Fuel Systems

Solid Fuel Systems Interest in waste to energy technology, especially biomass energy, has increased dramatically over the last few years as industry is faced with increased restrictions on emissions of greenhouse gases and rising coal prices. Most solid recovered fuels are not handled as discrete pieces like whole tires but ...

Learn More

Learn More

Multi-Fuel Systems

Multi-Fuel Systems In the waste-to-energy world, all fuel is local. For maximum control of process and fuel costs, cement plants need the flexibility to implement whole tires and waste derived fuels from multi-fuel systems. When tire fuel is used with other bulk solid fuels, AFS recommends the use of a ...

Learn More

Learn More

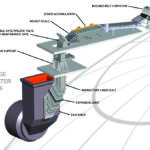

Mid-Kiln Fuel Systems

Mid-Kiln Fuel Systems AFS Technology offers a complete turnkey whole tire fuel handling system to feed existing long wet/dry kilns. The automated system is designed to feed whole tires from trailer to kiln. Its mid-kiln valve allows tires to be placed midway along the length of a rotating kiln, where temperatures are ...

Learn More

Learn More

4-Stage Preheater Fuel Systems

4-Stage Preheater Fuel Systems Typically 4-Stage preheater kilns are the most cost effective kilns to equip for whole tire fuel; providing a 15% to 20% fuel replacement rate and a return on investment in the range of 12 to 24 months depending on the tire fuel availability and cost or ...

Learn More

Learn More

Precalciner Fuel Systems

Precalciner Fuel Systems Typically, the maximum fuel substitution for whole tires introduced on or falling to the feed shelf in Precalciner Kilns is less than 5%. Above this rate, the sulfur cycle volatilization in the kiln is too high to maintain stable operation without a significant loss in production. To ...

Learn More

Learn More

Scrap Tire Handling

Scrap Tire Handling Our materials handling systems have been specifically designed for scrap tires. The equipment involved automates many of the labor-intensive tasks relating to unloading, storing, sorting and transport of scrap tires to their end-use point. Tire Handling System configurations can be customized to fit your space allotment and ...

Learn More

Learn More