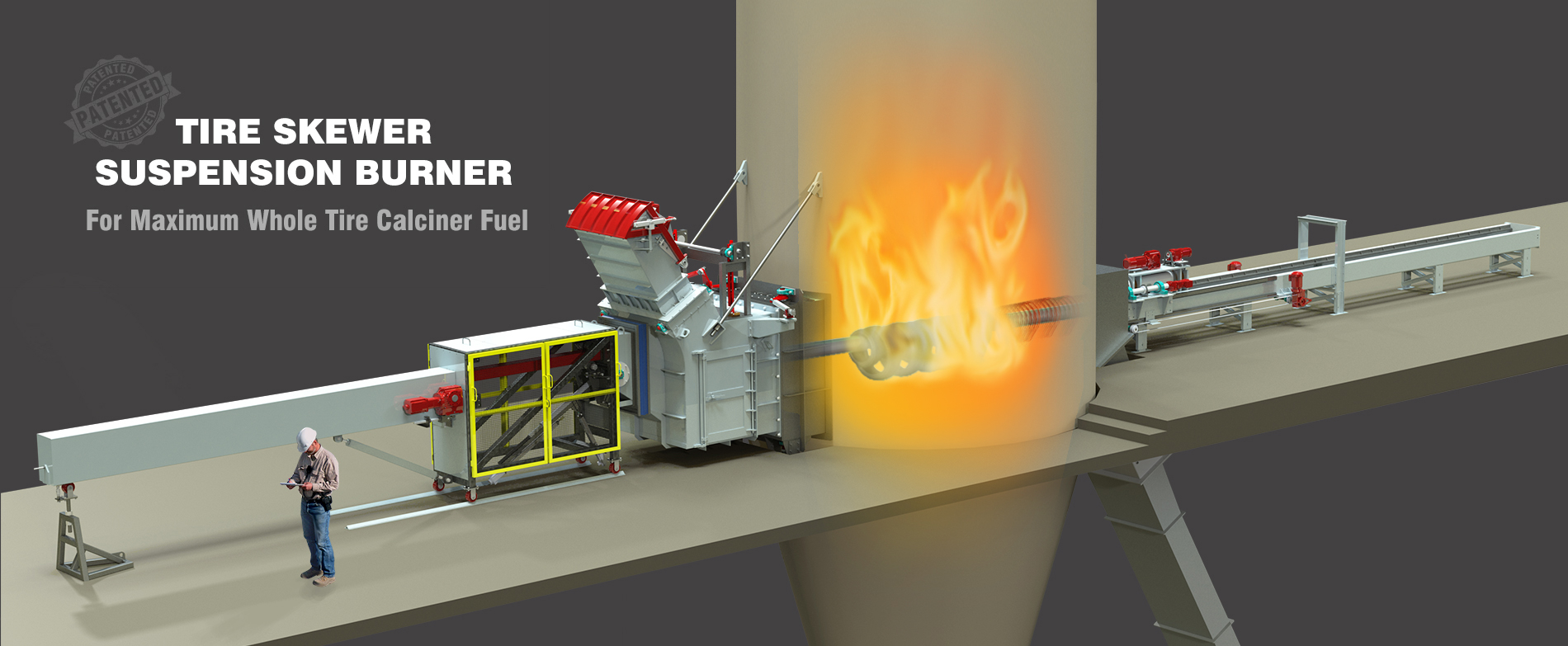

Tire Skewer Suspension Burner

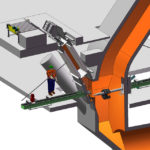

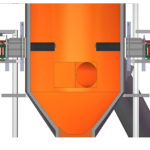

AFS Technology’s patented Tire Skewer Suspension Burner takes advantage of the doughnut shape of the tire to hold it in suspension for 100% fixed carbon burnout. With this method, multiple tires can be securely suspended in the high gas velocities of the riser duct or feed shelf hood for maximum NOx reduction benefit. Field testing has demonstrated feed rates exceeding 3 tons/hr for sustained periods, and possibly working over 6 tons/hr using two burners.

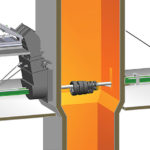

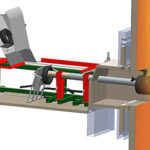

Essentially there are two types of Tire Skewer Suspension Burners; the cantilevered and the spanning. Each is based on the calciner diameter and the method tires are loaded on the skewer rod. Large diameter calciners will normally require the cantilevered version, while smaller diameter calciners will use the spanning version.

KILN TYPES: Precalciners

FUEL INJECTION LOCATION: Calciner above tertiary air, riser duct below tertiary air, or feed shelf hood

- Temperature: 900 – 1100 degrees Celsius

FUEL FEED RATE: 3-4 tons per hour (t/h), per burner – with no sulfur build-up issues

FUEL SPECIFICATIONS: Whole scrap tires up to 48 in (1220 mm) in diameter

SYSTEM OPTIONS: Wire Cutting option drops tire wire onto the feed shelf. Wire recovery option removes wire from the kiln process

SYSTEM COMPONENTS (Full Automation):

Double-Gate Airlock Valve | Tire Skewer | Weigh Feed Conveyor | Electrical Controls | Zoned Accumulation Conveyor(s) | Vertical Conveyor | Automated Ground Systems