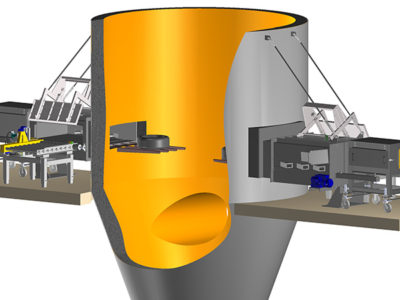

Rack Suspension Burner

Our Rack Suspension Burner is designed to feed whole tyres onto a high-temperature alloy Suspension Rack – also known as the “fork” or “fingers” – which enables the tyre to remain in suspension while burning inside the walls of the calciner. Typically placed above the tertiary air duct, ample oxygen levels aid in the complete combustion of fixed fuel carbon well above the feed shelf. Multiple burners can be installed to achieve tire fuel substitution rates over four times greater than feed shelf firing methods.

Our Rack Suspension Burner is designed to feed whole tyres onto a high-temperature alloy Suspension Rack – also known as the “fork” or “fingers” – which enables the tyre to remain in suspension while burning inside the walls of the calciner. Typically placed above the tertiary air duct, ample oxygen levels aid in the complete combustion of fixed fuel carbon well above the feed shelf. Multiple burners can be installed to achieve tire fuel substitution rates over four times greater than feed shelf firing methods.

KILN TYPES: 5 or 6-Stage Inline Precalciners; Custom design for certain types of Separate Line Calciners.

FUEL INJECTION LOCATION: In the calciner, typically above the tertiary air.

- Temperature: 900 – 1100 Degrees Celsius

- Gas Velocity: <10 Meters per Second

- Oxygen: >2%

FUEL SPECIFICATIONS: Whole scrap tires up to 48 in (1220 mm) in diameter.

FUEL FEED RATE: One-to-1.5 Tons Per Hour (TPH), per burner.

TEMPERATURE RATING: 1100 Degrees Celsius

ADDITIONAL FEATURES:

- Four individually removable self cleaning suspension fork tines made of a high temperature alloy rated for 1100° C in high sulfur gas conditions.

- Airlock chamber will be made of 304 stainless steel

- High temperature pivoting style interior gate made of stainless rated for 1100° C

- Pivot/knife style exterior gate made of 304 stainless

- Ram supported and guided by 4 heavy duty flanged cam rollers, driven by a rack and pinion

- Refractory lined nozzle mounted to the side wall of the combustion chamber.

- High temperature maintenance gate with two manual refractory lined sliding gates in a refractory lined housing.

SYSTEM COMPONENTS (Full Automation):

Suspension Burner | Weigh Feed Conveyor | Electrical Controls | Zoned Accumulation Conveyor(s) | Vertical Conveyor | Scrap Tire Handling System