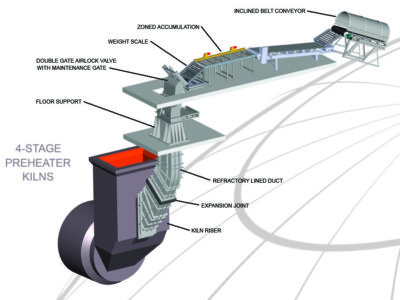

4-Stage Preheater Fuel Systems

Typically 4-Stage preheater kilns are the most cost effective kilns to equip for whole tire fuel; providing a 15% to 20% fuel replacement rate and a return on investment in the range of 12 to 24 months depending on the tire fuel availability and cost or revenue. We accomplish this using an AFS double gate airlock valve to feed (roll) the tires over the backend feed shelf and into the kiln.

SYSTEM COMPONENTS (Full Automation): Double-Gate Airlock Valve; Weigh Feed Conveyor; Zoned Accumulation Conveyor(s); Hook Elevator; Ground System Tire Receiving & Handling Automation

FUEL SPECIFICATIONS: Whole scrap tires up to 48″ in diameter; chipped or shredded Tire Derived Fuel; other high-density Bulk Solid Fuels.

FUEL FEED RATE: AFS Technology provides weight-based feed rate systems to enable precise feed rate control. This is achieved by weighing each tire individually and basing tire injection timing intervals on the tire weights. AFS can provide a wide range of weight controller analog or digital interfaces.

FUEL SUBSTITUTION RATE(S): 4-stage preheater kilns typically achieve 15-20% whole tire fuel substitution rates. Higher rates are possible with a mixing air fan system.

RETURN ON INVESTMENT: Typically 12-24 months.